Table of Contents

Let’s be real for a second. When you see cities turned to rubble—schools, hospitals, homes, entire neighborhoods wiped out by war—it hits you in the gut. You wonder, How do people even start again? And then you realize: it’s not just about bricks and mortar. It’s about giving people back their dignity, their safety, their future. That’s why we at Rucobond Aluminum Composite Panel Co., Ltd. don’t just make building materials—we believe we’re helping rebuild lives.

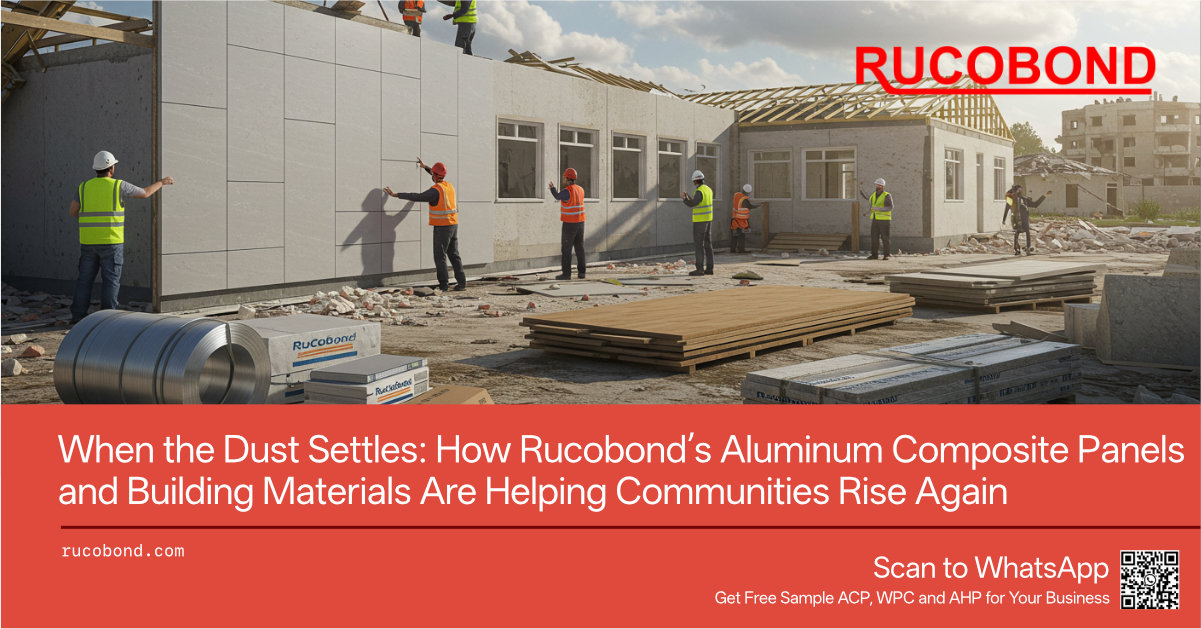

We’ve been doing this since 2013, right here in Guangzhou, China. Over a decade of making aluminum composite panels, aluminum honeycomb panels, wood-plastic composite boards, sintered stone slabs, aluminum coils, and aluminum veneer—not just for fancy skyscrapers or shopping malls, but for places that need to stand strong. And now, more than ever, we’re turning our focus to regions shattered by conflict: Ukraine, Gaza, Syria, Yemen, and beyond. Wherever war has left scars, we want to help lay down something better—something lasting.

We’re not a charity. We’re a manufacturer. But that doesn’t mean we can’t care. In fact, we think caring is what makes us different.

You know those buildings that go up in weeks, not years? A lot of the time, they’re using Aluminum composite panels (ACP)—ACP. And yeah, we make some of the best. Our ACPs come in solid flat, metallic finish, mirror, wood grain, brushed silver, brushed gold—you name it. But it’s not just about looks. These panels are fire-rated, weather-resistant, and tough as nails. We’ve seen them hold up in typhoons in the Philippines, scorching heat in Saudi Arabia, freezing winters in Eastern Europe.

When you’re rebuilding a school in Kyiv or a clinic in Gaza, you can’t afford to wait. You need materials that are easy to install, lightweight, and won’t crack under pressure—literally. That’s why our ACP is used in temporary shelters that become permanent homes, in government buildings that need to look strong, and in commercial spaces that bring jobs back to communities.

We’ve shipped container after container to reconstruction zones, and every time, we get messages back: “These panels arrived fast. They went up faster. People are already moving in.” That’s not just logistics. That’s impact.

Now, if you’re working on airports, train stations, or big public buildings, you need something that doesn’t sag, warp, or buckle. That’s where our aluminum honeycomb panels come in. They’re made with a core that looks like a beehive—hence the name—but don’t let the delicate image fool you. This structure makes them super rigid while keeping them super light.

We once supplied a project in Thailand where they were rebuilding a community center after a bombing. The roof had to span wide without support columns—so they needed something strong but not too heavy. Our honeycomb panels did the job. No sagging after two monsoon seasons. No warping in the sun. And the best part? They saved on structural steel because the panels carried their own weight.

That’s the kind of advantage you don’t always see on paper—but you feel it when the building stands tall.

Let’s talk about flooring. When families are displaced, they often end up in shelters with concrete floors or flimsy mats. Cold, damp, uncomfortable. But our wood-plastic composite (WPC) boards? They look like real wood. They feel warm underfoot. And they don’t rot, warp, or get eaten by termites.

We’ve seen WPC used in refugee housing in Jordan, in temporary classrooms in Ukraine, and in rehab centers in the Philippines. It’s not just about comfort—it’s about dignity. A kid should be able to sit on the floor and do homework without getting sick from mold. A grandmother should be able to walk without slipping.

And because WPC is 100% recyclable and made from recycled wood and plastic, it’s kinder to the planet, too. Rebuilding shouldn’t mean trashing the environment all over again.

You might think marble-look sintered stone slabs are just for fancy kitchens. But we’ve seen them used in field hospitals, in rebuilt town halls, in memorials for the fallen. Why? Because they’re hygienic, scratch-resistant, and UV-stable. Sunlight won’t fade them. Knives won’t scar them. Blood, iodine, disinfectants—wipe them off, and the surface stays pristine.

One customer in Israel used our sintered stone for a trauma center near the Gaza border. They needed surfaces that could handle constant cleaning, high traffic, and emotional weight. Our slabs didn’t just perform—they brought a sense of calm, of normalcy, to a place that sees too much chaos.

That’s the hidden benefit of good materials: they don’t just function. They heal.

Behind every sleek building facade, there’s usually aluminum coil. We produce high-grade coils that can be coated, embossed, or cut to size for custom projects. And our aluminum veneer? It’s like the luxury skin of modern architecture—lightweight, corrosion-resistant, and perfect for curved walls or complex designs.

We’ve worked with contractors in Saudi Arabia who used our aluminum veneer to rebuild entire housing blocks in weeks. The material arrived pre-finished, so no painting, no delays. Just bolt it on, and move in.

When time is short and budgets are tight, that kind of efficiency isn’t just nice—it’s essential.

Look, we know it’s not easy being a procurement officer in a war zone. You’ve got supply chain nightmares, security risks, language barriers, and people depending on you. That’s why we don’t treat orders like transactions. We assign real people to your project—someone who answers emails at 2 a.m., who tracks your containers, who helps you choose the right panel thickness for your climate.

And if you’re doing a big job—like rebuilding a whole village or a hospital complex—we can do OEM and ODM. That means your brand on the product, your specs, your packaging. We’ve done it for companies in the U.S., Thailand, and Germany. Doesn’t matter if you’re a construction firm, a trading company, or an NGO with a mission—we’ll work with you.

We’ve even offered special pricing and extended payment terms for humanitarian projects. Because when it comes to rebuilding lives, profit shouldn’t be the first thing on the table.

We’ve got the SGS reports. The CE marks. The ISO 9001 certification. We test every batch. We keep records for years. Not because it looks good on a website, but because when a bomb hits and a wall stays standing, it’s because someone did their job right.

We’ve had third-party labs in Europe test our ACP fire ratings. Passed Class B1 and EN 13501-1. Our honeycomb panels? Tested for wind load, impact resistance, thermal expansion. We don’t hide behind marketing fluff. We show you the data.

And yeah, we’re based in China—but our standards? Global.

Every time a school opens, a clinic reopens, or a family moves back into a home, it’s a small victory. And we’re proud to say our materials are part of that story. From the aluminum composite panels on the roof to the wood-plastic composite under someone’s feet, we’re there.

We’ve gotten photos from the field—kids drawing on walls made with our ACP, workers smiling in front of a building wrapped in our aluminum veneer. That’s what keeps us going.

If you’re involved in reconstruction—whether you’re a building materials trader, a contractor, or part of an aid organization—we want to help. We can handle large orders. We can customize. We can ship fast. And we can offer real support, not just a PDF catalog.

Because rebuilding isn’t just about putting up walls. It’s about giving people hope. And if our aluminum composite panels, aluminum honeycomb panels, wood-plastic composite boards, sintered stone slabs, aluminum coils, or aluminum veneer can play a part in that, then we’re not just selling products.

We’re doing something that matters.

So reach out. Let’s talk. Let’s build.

Name: Gina Chen

Mobile:+86-189-2412-4951

Tel:+86-189-2412-4951

Whatsapp:8618924124951

Email:gina@rucobond.com

Add:No.9 Building, Loteam Industry Park, Huangge Town, Nansha District, Guangzhou, China